We’re dedicated to demonstrating our ability to produce and supply scandium for different types of applications, sectors, and industries.

A new key player enters the stage

Through our sustainable refining process, recently developed by our teams at the Element North 21 plant and Technology and Critical Minerals Centre located in Sorel-Tracy, Quebec, we remain more committed than ever to produce pure scandium oxide with minimal impact to the environment.

Securing the supply chain

Currently in the early stages of development, the Element North 21 plant has the capacity to produce three tons of scandium oxide annually, which represents about 20% of the global supply.

A well-defined traceability

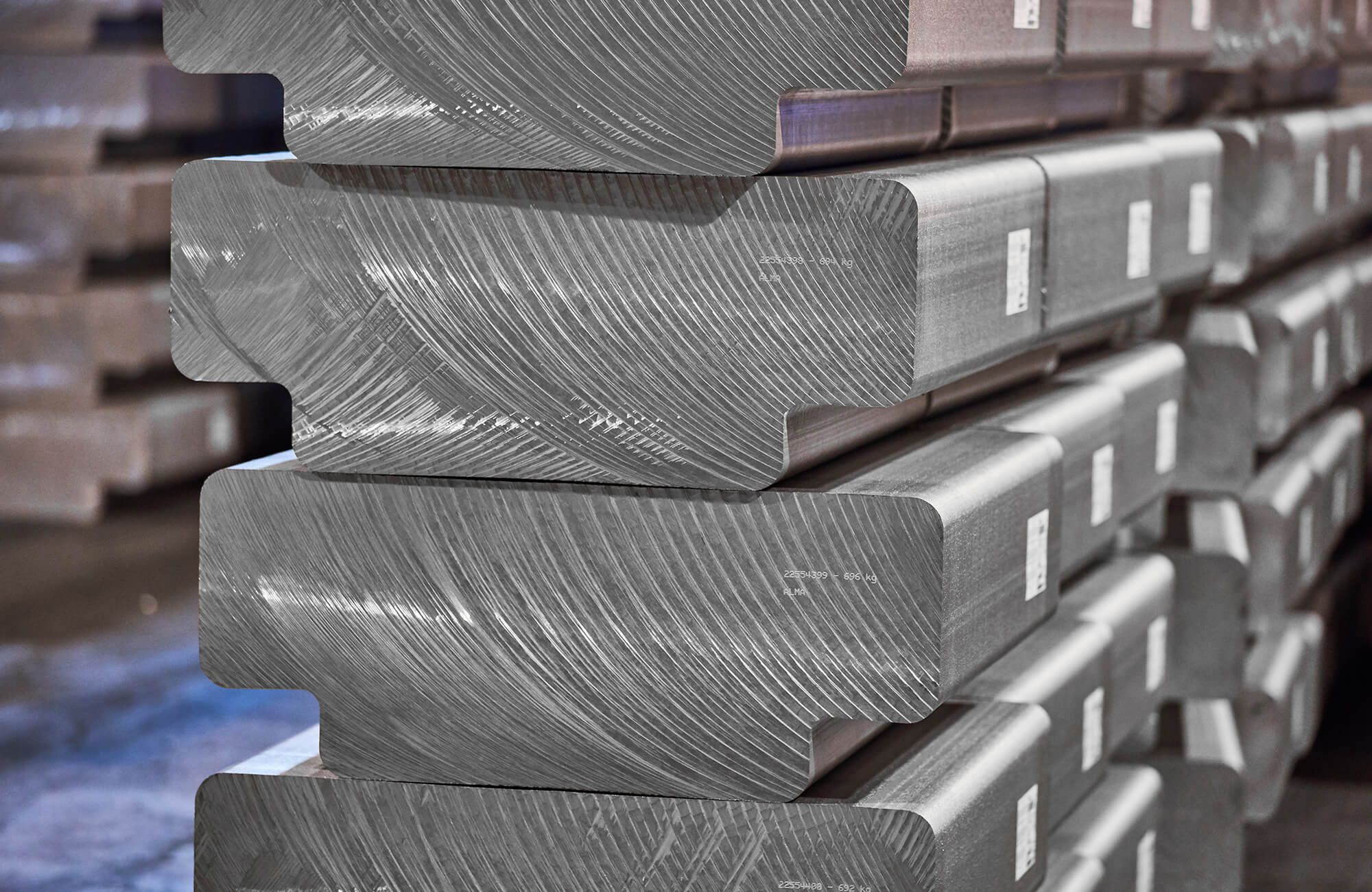

Sourcing scandium from RTIT Quebec Operations provides access to the silvery-white metallic substance with a clear traceability link, as dictated by our mining and production standards, protocols and environmental criteria.

Mastering the art of extracting and producing a rare earth element

We’ve managed at RTIT Quebec Operations to devise and hone a cutting-edge extraction and production technique in line with the global energy transition that allows us to recover an exceptionally beneficial rare earth element: scandium.

Our sustainable proprietary process, which uses spent acid collected from our titanium slag production in Quebec, has pushed the production of scandium oxide and aluminium alloys to a whole new level.

As scandium specialists, we’ve succeeded in our mission to provide a high-purity critical element that allows for aluminium alloys of high performance with increased lightness and strength, ensuring in turn the next evolution for multiple business sectors and our global economy.