Considered a critical mineral by a number of countries, including the United States, Canada and Australia, scandium is a versatile and useful resource that allows global manufacturers and industries to redefine the limits of design and production process.

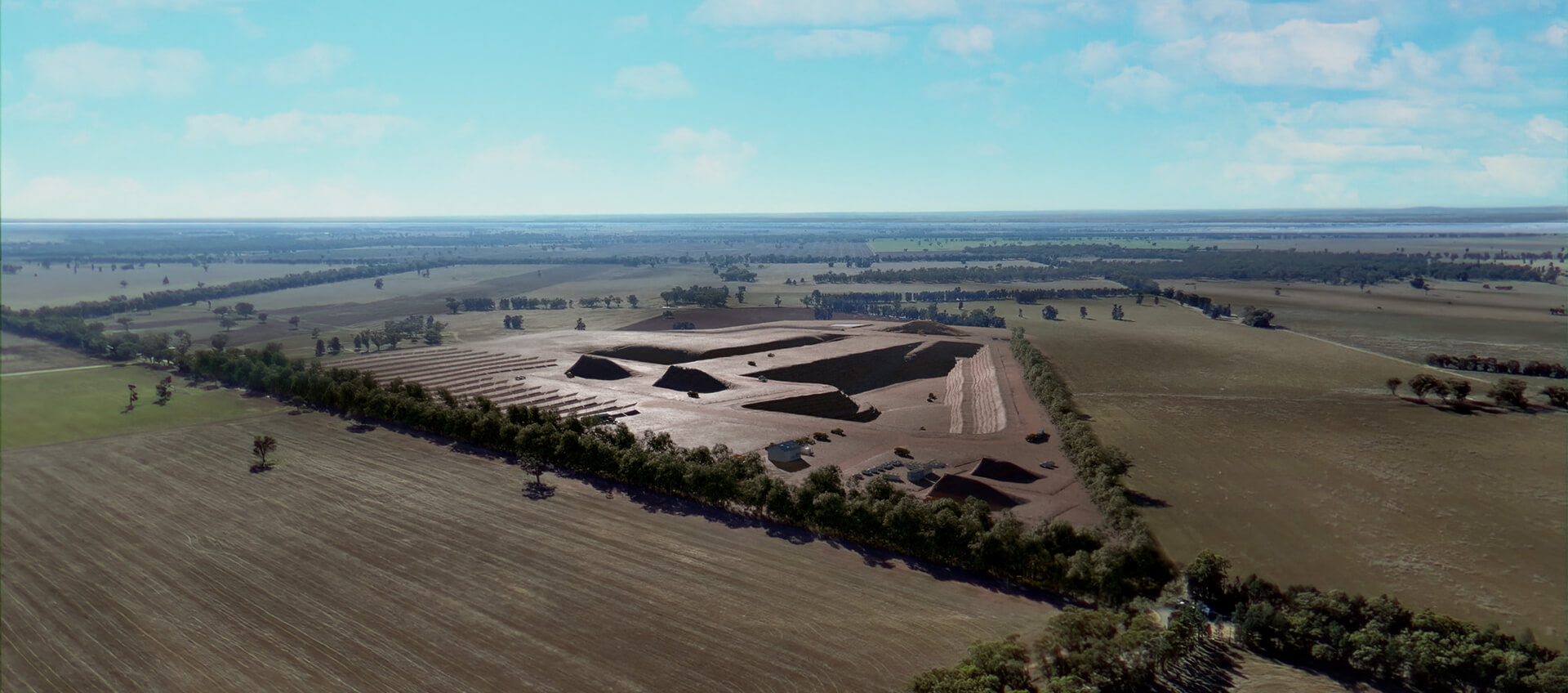

Located in New South Wales, Australia, this new undertaking seeks to deliver a long-life, high-grade scandium resource. Despite its small footprint, it has the potential to become the primary scandium operation in Australia and globally.

Find out how we developed a new way to extract and produce high-purity scandium oxide from the waste streams of titanium dioxide production, without the need for any additional mining.

Product purity

High purity scandium oxide

Strength improvement

Typical mechanical limit increase for each 0.1% addition of scandium in aluminium alloys

Thermal resistance

Aluminium-scandium alloys can withstand temperatures of up to 600°C with limited performance degradation

Maximize decarbonisation

Aluminium-scandium alloys help produce lighter components, optimizing energy efficiency during the manufacturing process